When a car wheel spins fast, it seems as if the rim slowly turns in an opposite direction. The human eye is simply no longer able to follow the wheel’s speed, i.e. the number of pictures per second. This image looms, if one learns how quickly the machines of Belvac Decorating Systems supply, print and remove cans. It comes with hundreds at once per minute.

Can technology

We are visiting Belvac, formerly Rosario, in Dongen (North Brabant). Rosario arose from a brewery. It steadily grew as a company committed to the maintenance of the Coca Cola USA bottling line. The name Rosario is derived from the place Rosario in Argentina, where the founder bought hides for processing into leather. In 1967 Hein van Tuyn transformed the company into a company that manufactured spare parts and gradually designed and built more and more conversion machines. Finally in 1971 Rosario Can Technology came about with currently more than 20 employees. The company is ambitious and targets on sales growth every year.

36 cans per second

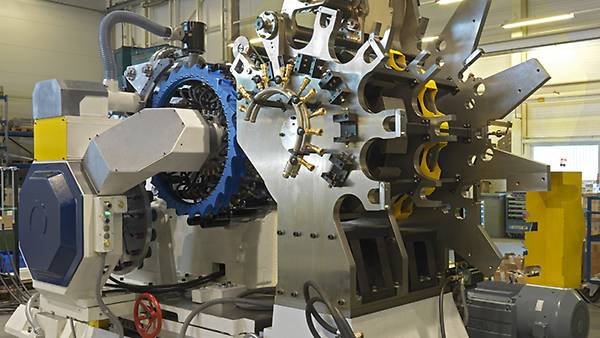

Rosario made his name at home and abroad when it specialized in the design and construction of complete machines for printing of two-piece aluminum cans. These are used in the beverage and food industry. On YouTube one can see how fast the machine prints the aluminum cans, up to 36 per second (2,200 per minute!).

Hein van Tuyn is the grandson of the founder and son of the current managing director. He is responsible for the PR and sales of the base coating machinery and decorators, as the can printing machines are called. His customers are the factories at home and abroad that manufacture the aluminum cans.

There is an increasing amount of factories, especially in South America and Asia. He tells that Rosario integrated into the American Belvac Decorating Systems at the beginning of this year. This multinational is a major player in the field of design and manufacturing of continuous-rotation machines. These machines are used by beverage producers around the world.

What's so special?

What differentiates Rosario/Belvac of his competitors in the market? Hein van Tuyn: "Our machines are unique for their very low down time, the processing speed and the modular (standard) construction. This standard construction provides flexibility in the processing of different can sizes. "Belvac focuses particularly on innovation and assembly of machines and attaches great importance to a reliable, smooth operation.”

Van Tuyn: "Therefore we opt for the drive technology from vendors that we know well and with whom we have fine experiences. After that we seldom switch."

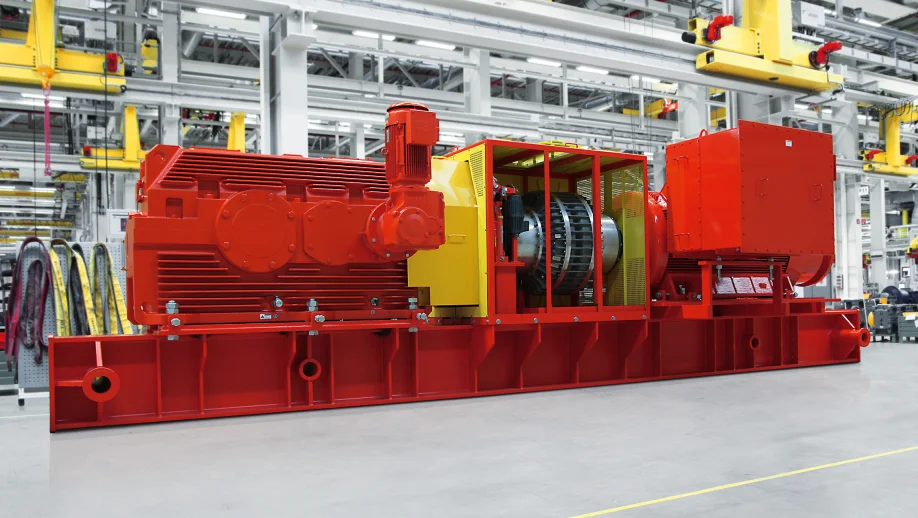

The company has been using the asynchronous electric motors from SEW-Eurodrive as a default for years now. “We are familiar with these motors and the value for money is good. In addition, SEW is able to supply fast, also abroad."

IEC motors from SEW-EURODRIVE

Belvac builds approximately six to eight machines per year in Dongen. These are provided with asynchronous electric motors from SEW-Eurodrive for the drive of the main shaft and the varnish drive.

The 2, 4 and 6 pole IEC three-phase induction motors of SEW-Eurodrive are modular, meet all efficiency classes to IE3 and are therefore applicable worldwide. The electric motors have a power range from 0.12 kW to 200 kW.

Because of the modular design with many options, such as brakes, encoders, cooling fans, temperature monitoring, special coating and surface protection, the most appropriate motor can be selected for each machine. For example, the motor can be provided with a foot or a flange, or assembled in an aseptic version.

As to Belvac the options are not that important. The company knows what it wants and relies on SEW to supply impeccably. So there is time left for the core activity: innovation and assembly of the own machines. This way creative mechanics of Rosario/Belvac designed a lever by means of which ink modules can easily be exchanged without first having to disassemble the whole machine, resulting in a substantial gain in time.

Yes, Belvac Decorating Systems can.

Components and solutions used

Quote from Hein van Tuyn, responsible for sales and promotion of the base coating machinery

"We opt for the drive techniques of suppliers we know very well and with whom we made good experiences. Then we do not switch very easily.” "Our machines stand out for their very low down time,

their large processing speed and the modular (default) construction. This standard arrangement guarantees a smooth processing of different can sizes."

Contact

Feel free to contact us.

Do you need advice on a specific application? Just send us a message with your questions.

Inquire now