One of those plastic products is the stretch film that is tightly wrapped around goods on pallets, so that they can be transported safely. The film ensures stable pallets and thus prevents damage to the goods during transport. There are stretch films for the transport of (frozen) food, chemical products, animal nutrition, insulation, soft drinks, paper and cardboard and dairy. If the packaging of these products is damaged during transport, the consumer will ignore them.

Trioworld: Re-thinking plastic

New name Trioworld

Trioworld is the new name for Europe's market leader in sustainable polyethylene film solutions. The company was formed after a merger of Trioplast and AFP, since 1965 two of the largest players in Europe in the field of plastic film.

The company employs 1,200 people and achieves an annual turnover of more than € 550 million. It is headquartered in Sweden and has production sites in Sweden, Denmark, the Netherlands and France. The products are sold worldwide.

Collaboration with SEW

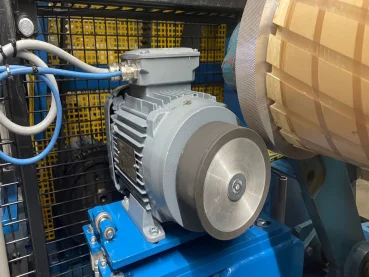

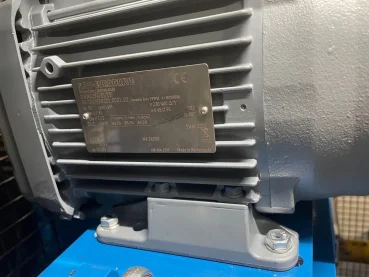

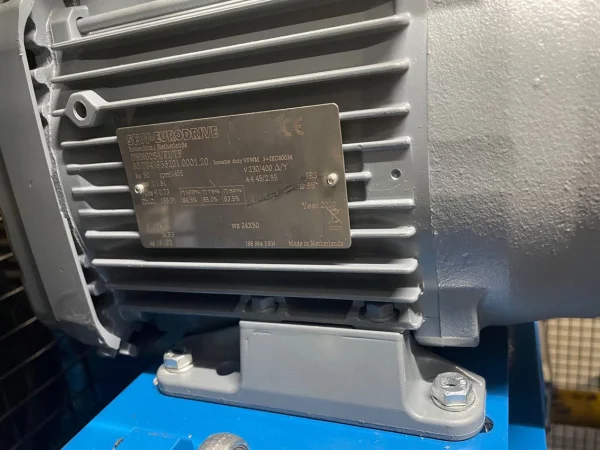

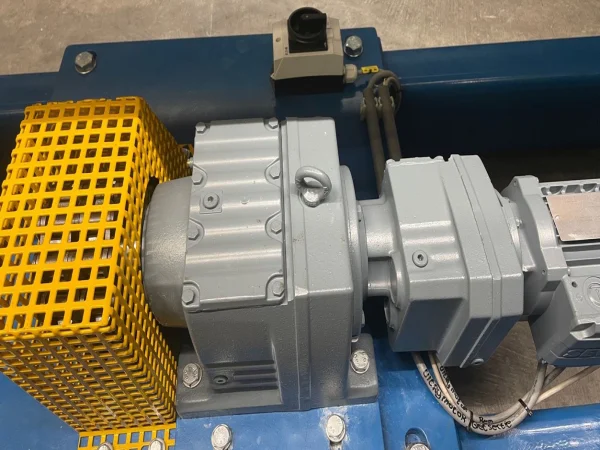

Our drive specialists, together with Trioworld, helped to create a well-applicable drive for the redesign of one of the casting sections. As a result, this casting section is completely ready again for the production of the latest films for the food industry, among others. For the displacement of the casting section, an SEW geared motor, type R67 R37 DRN63 was selected and for the winding roller a SEW motor, type DRN90S4.

Stretchfilm to protect value

If the packaging of these products is damaged during transport, the consumer will ignore them. Good protection therefore ensures the preservation of value.

Project impressions

SEW' sales engineer Peter Boermans:

Thank you for the teamwork @Jeroen Nijland and @Peter Bredenhoff!

Components

Satisfied customer

Do you also want to develop a new machine or improve an existing installation? We are happy to think along with you!

Feel free to contact us info@sew-eurodrive.nl.

More information on Trioworld: www.trioworld.com