Our application solution for corner transfer units and rotary tables provides you with innovative drive components with decentralized or sequential drive control. Its unique technical characteristics allow you to implement more cost-efficient planning for your systems.

Distinguishing features of the corner transfer unit/rotary table

Corner transfer units and rotary tables are used for routing the flow of materials on conveyor lines. They ensure the smooth sorting and discharging of the material to be conveyed. To create the optimal flow of materials, corner transfer units and rotary tables synchronize with the conveyor processes, This in turn requires corresponding interfaces to the higher-level system control. With our application solution for corner transfer units/rotary tables, you can adjust the standard to fit your system, and increase efficiency without any difficulty.

Our solution provides you with concepts that include modern drive components. Optimized processes and the simple assignment of components during installation provide you with project management support. Predefined application modules make startup quick and easy, allowing you to profit from high system and drive component availability. Even more: the decentralized drive concepts greatly simplify installation and maintenance.

Your benefits

-

High drive technology availability

because our solution provides for corner transfer units/rotary tables you with concepts that include modern drive components. -

Optimized processes

with the easy assignment of components to their functions, you significantly optimize your processes. -

Application-specific documentation

package-specific documentation offers a high level of process reliability and risk minimization. -

Optimized performance and costs

this solution represents a reduction in both the complexity of the system and the time and effort expended on installation. In this way, you reduce your operating costs. -

Quick startup

with predefined application modules, startup is quick and uncomplicated. -

Predefined software module

Your major benefit: You only required one software package for consistent engineering.

Predefined variants for the perfectly tailored solution

Rotary table with Sequential Drive Control

Guide unit loads in all directions – thanks to the sequentially controlled rotary table.

Rotary table as distributor

Efficient conveyor concepts for extensive systems as well

Rotary table for decentralized rotary table concepts

Intelligent material handling in compact systems – with the decentralized rotary table

The package corner transfer unit in the rotary table for decentralized rotary table concepts: the ideal solution for optimized drive and control concepts. This concept is the perfect match for the conveyor line for decentralized conveying concepts, making it possible for you to implement compact conveying systems.

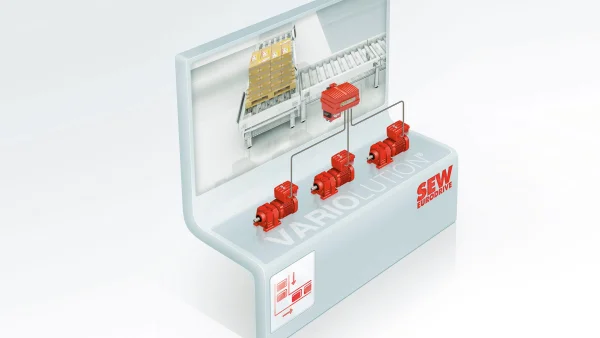

Corner transfer units for decentralized corner transfer unit concepts

You can also benefit from the advantages of this solution variant.

This variant is the optimal cost-effective addition to the conveyor line for decentralized conveying concepts. This combination makes it possible for you to implement compact conveying systems with uniform components in a simple, modular fashion. Only one decentralized MOVIFIT® MC controller controls the three MOVIMOT® drives.

Single-axis rotary table

The perfect solution for modular drive and control concepts

Rotary table with control cabinet technology

Modular conveyor lines in control cabinet layout

The package corner transfer unit in the rotary table with control cabinet technology variant optimally supplements the conveyor line with control cabinet technology. This combination enables you to create modular conveyor lines with a classic control cabinet layout. With the cost-optimized MOVITRAC® LTE inverter, SEW‑EURODRIVE provides the perfect solution for traditional conveyor lines.

Distinguishing features of the corner transfer unit/rotary table

Corner transfer units and rotary tables differ in terms of sorting possibilities and control concepts. The corner transfer unit package’s predefined variants make it easier for you to choose the right components.

Rotary table with control cabinet technology and corner transfer unit for decentralized corner transfer concepts

| Distinguishing features | Rotary table with control cabinet technology | Decentralized corner transfer concept |

|---|---|---|

| Rotary table | + | – |

| Corner transfer unit incl. lifter | – | + |

| Reduced effort for installation, cabling, and maintenance | – | + |

| Reduction of components/controllers per station | '1:1 | '1:3 |

| Energy-efficient drive technology | – | + |

| SEW‑EURODRIVE product series | MOVIFIT® LT, DR.. geared brakemotors | MOVIFIT® MC, MOVIMOT®, DR.. geared brakemotors |

| Performance | Up to 11 kW | Up to 4 kW |

| Accuracy/controllability | – | – |

| Overload capacity | 150% for 60 s | 100% |

| External bus systems (optional) | SBus | PROFIBUS, DeviceNet, ProfiNet, Ethernet IP, Modbus TCP |

| Internal bus system | RJ45 | RS-485 (CAN) |

| Segmentation/modularity | Complete modularization to one segment | Yes – self-sufficient combination of up to 3 modules |

| Ambient conditions/workplace regulations (optional) | Extremely harsh ambient conditions (motor up to IP66; OS4) | Harsh ambient conditions (MOVIMOT® to IP66; surface protection OS1) |

| Brake | Optional | Mandatory |

Rotary table with decentralized drive control and rotary table as distributor

| Distinguishing features | Decentralized rotary table concept | Rotary table as distributor |

|---|---|---|

| Rotary table | + | + |

| Corner transfer unit incl. lifter | – | – |

| Reduced effort for installation, cabling, and maintenance | + | + |

| Reduction of components/controllers per station | '1:3 | Max. 1:10 |

| Energy-efficient drive technology | + | + |

| SEW‑EURODRIVE product series | MOVIFIT® MC, MOVIMOT®, DR.. geared brakemotors | MOVIGEAR® SNI B |

| Performance | Up to 4 kW | Up to 400 Nm per segment |

| Accuracy/controllability | – | + |

| Overload capacity | 100% | Approx. 300% |

| External bus systems (optional) | PROFIBUS, DeviceNet, ProfiNet, Ethernet IP, Modbus TCP | PROFIBUS, DeviceNet, ProfiNet, Ethernet IP, Modbus TCP |

| Internal bus system | RS-485 (CAN) | SNI |

| Segmentation/modularity | Yes – self-sufficient combination of up to 3 modules | Yes – self-sufficient combination of up to 10 modules |

| Ambient conditions/workplace regulations (optional) | Harsh ambient conditions (MOVIMOT® to IP66; surface protection OS1) | For areas with hygienic design regulations (IP69K); for clean rooms (IP65) for workplaces with persons (very low noise generation) |

| Brake | Optional | None – only DynaStop® |

Rotary table with control cabinet technology and corner transfer unit for decentralized corner transfer concepts

| Distinguishing features | Rotary table with control cabinet technology | Decentralized corner transfer concept |

|---|---|---|

| Rotary table | + | – |

| Corner transfer unit incl. lifter | – | + |

| Reduced effort for installation, cabling, and maintenance | – | + |

| Reduction of components/controllers per station | '1:1 | '1:3 |

| Energy-efficient drive technology | – | + |

| SEW‑EURODRIVE product series | MOVIFIT® LT, DR.. geared brakemotors | MOVIFIT® MC, MOVIMOT®, DR.. geared brakemotors |

| Performance | Up to 11 kW | Up to 4 kW |

| Accuracy/controllability | – | – |

| Overload capacity | 150% for 60 s | 100% |

| External bus systems (optional) | SBus | PROFIBUS, DeviceNet, ProfiNet, Ethernet IP, Modbus TCP |

| Internal bus system | RJ45 | RS-485 (CAN) |

| Segmentation/modularity | Complete modularization to one segment | Yes – self-sufficient combination of up to 3 modules |

| Ambient conditions/workplace regulations (optional) | Extremely harsh ambient conditions (motor up to IP66; OS4) | Harsh ambient conditions (MOVIMOT® to IP66; surface protection OS1) |

| Brake | Optional | Mandatory |