At the banks of the river Nederrijn in Renkum (NL) the Parenco paper factory has been the Dutch center of the paper industry since 1912. For years Parenco’s main product was newsprint. However, as the demand for newsprint began to fall in the early years of 2000, Parenco had to blaze a new trail. In 2010 SCB grade was successfully implemented.

Optimal drive solution for Parenco in Renkum (NL)

Weighty remanufacturing at Parenco

Two paper mills

For the laymen: SCB grade is an improved paper type: Super Calandred B grade. Parenco still has two huge paper machines: PM1 produces graphic paper – SCB for printing of leaflets, and PM2 produces packaging paper (80 – 135 gram cardboard).

The machine’s capacity will be increased to about 380,000 tons in the coming years. As a matter of fact the demand for packaging paper in only growing, think of the annual increase of orders via internet ...

Therefore the company, having 260 employees, mainly supplies the packaging industry and printing businesses throughout Europe. The total production capacity is 585,000 tons per year.

Project impressions

Many drives

Parenco is an important customer of SEW-Eurodrive. The factory space is well provided with drives that ensure all necessary movements. Also subsidiary Reparco uses 'SEW' for assorting domestic multicolour paper that then again serves as raw material for Parenco.

Stable installations are of great importance to Parenco. That’s absolutely understandable in view of the size of the machines. Standstill may undermine the quality of the paper. For that reason, regular predictive maintenance takes place, followed by necessary revisions. Unfortunately not everything always goes according to plan, as Parenco’s Technical Department experienced last year.

Unexpected crash

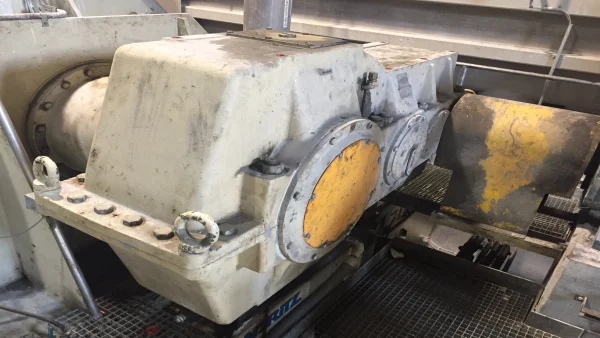

Early April 2017 Parenco asked SEW-Eurodrive to submit an offer for a gearbox as replacement for an 'old' Metso/Santasalo gearbox that was mounted in the dewatering press. This gearbox (type 3TC630N) was delivered to Parenco in 2001. The SEW settlement in Finland was able to assemble this gearbox, weighing 4.2 (!) tons (l x b: 2.28 x 1.43 m), but needed 20 weeks ...

However, reality gained upon Parenco, because on a Friday in May the gearbox that had to be replaced, broke down suddenly. It was dismounted immediately and inspected on the next day, on a Saturday at SEW in the Large Gearbox Workshop in Rotterdam. Instead of ordering a whole new gear unit, it was decided to have the defective unit overhauled completely and urgently. A delivery period of 8 working weeks was considered feasible with a commitment to try and speed up the delivery time to 5 weeks.

After five weeks

The defective gear unit was dispatched to SEW-Eurodrive in Finland. Upon arrival mechanics started replacing the whole interior immediately. The coupling was dismounted, and all pinions, gearwheels, bearings and seals were replaced. The housing that was still in a good condition, was thoroughly cleaned, blasted and painted. Eventually the revised gearbox, inclusive of the coupling, was returned to the customer – as new – after five weeks.

SEW technicians rendered support with respect to mounting, alignment and start-up, including a vibration measurement, of the gearbox. For the test run the gear unit was filled with more than 400 liters (!) of mineral oil.

The next mounting followed in October 2017, of a new Metso 3TC560N, that fortunately did not fail prematurely. By means of vibration measurements and inspections, however, damage was found.

Components and solutions used

Quote: Fred Dijkstra, maintenance engineer – Parenco Reparco

"SEW helped us swiftly and correctly last year. Communication is clear and we get along well. SEW feels for our needs, is able to supply quickly, has a wide product range and

takes care of a smooth follow-up. Because of this we can limit ourselves to a smaller stock.”

Contact

Feel free to contact us!

Do you need advice on a specific application? Just send us a message with your questions.

Contact us now