Many companies present a sustainable, transparent and green image of themselves, although they are not like that at all. In reality they still have to do a lot in order to do business in a real social corporate manner. Interface was one of the first to publicly commit itself to sustainability and actively proves that sustainability leads to a successful operational management. At this moment already more than 49% of its raw material is recycled or bio-based. For good reason the company received

Interface reduces energy consumption with MOVIGEAR®

Mission Zero

Interface is the world market leader in designing and manufacturing modular floor covering in the shape of carpel tiles. The originally Dutch company counts 3,500 employees worldwide, 275 of whom are active at the Scherpenzeel settlement. In 1994 the organization – as related by its founder Ray Anderson – promised not only to have eliminated its negative impact on the environment in the year 2020, but also to have made a recovering contribution. This promise has become known by the name of Mission Zero.

Geanne van Arkel, at Sustainable Business Development: “Mission Zero affects every decision and inspires the organization to continuously look beyond the existing business models, methods and solutions in order to reach this goal. Over the years we have reached nice milestones. For example already in 1996 ReEntry®, a program for the recollection of carpet tiles, was started. The introduction of TacTiles™ rendered glue superfluous when laying a carpet. And in 2011 Biosfera was introduced, a collection of tiles made of 100% recycled thread. This thread is made of regained thread and waste, such as used fishing nets.”

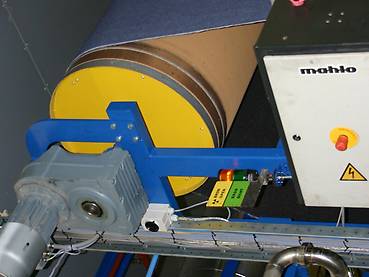

Project impressions

Logical cooperation

The cooperation between SEW-EURODRIVE and Interface is logical. Drives as part of a machine account for the bulk of the energy costs. SEW has been working on making drives more energy-efficient for years. An example is the DR motor that complies with the new energy standards worldwide (IE1…4) and the strict Ecodesign directive 2009/125/EG. Also the MOVIGEAR®, a low-energy mechatronic drive system, provides for considerably less CO2 emission. Geanne van Arkel: “The fact that these energy-efficient products cost slightly more, does absolutely not prevent us from buying them. If the return on investment period is known and the advantage for the environment is proven, these products will be applied.” In this way SEW-EURODRIVE contributes to Interface’s Mission Zero.

Energy efficiency through MOVIGEAR®

The extremely efficient MOVIGEAR® consists of a motor, gear unit and electronics in a very compact mechatronic unit. Its outstanding overload behavior means that it is ideally suited to the special requirements of carpet transportation technology and can reduce the variants in use while significantly reducing the installed power and saving energy. The benefits of the MOVIGEAR® primarily include the motor's extremely high efficiency IE4 (Super Premium Efficiency), which makes it an energy saving and reliable drive solution. Interface appreciated these benefits and they selected SEW-EURODRIVE as the innovative drive technology manufacturer to cooperate in reaching its Mission Zero objective.

- Energy savings

- Variant reduction to 7 installed drive configurations

- Reduction in the installed power

- Reduced installation and startup costs

- Faster and easier access to all parameters

- Plug-in design ensures a quick exchange

Customer request

Interface wanted to install reliable and powerful drives to upgrade the carpet transportation system. This meant that the key criteria were absolute reliability, energy efficiency and a reduction in the number of variants.

Our solution

With amonst other our mechatronic drive technology with MOVIGEAR®, Interface is able to reach its objectives: to have eliminated its negative impact on the environment in 2020 and to make a recovering contribution.

Components and solutions used

Quote: Geanne van Arkel, Sustainable Business Development from Interface

It inspires us to look further than the existing business models. Along the way we have reached beautiful milestones. Already n 1996 the ReEntry® was introduced, a take-back program for carpet tiles.

The introduction of TacTiles™ made the use of glue when placing carpets unnecessary. And in 2011 Biosfera was introduced, a collection of tiles made of fully recycled thread. This thread is made of recovered thread and waste, such as used fishing nets.

Contact

Feel free to contact us!

Do you need advice on a specific application? Just send us a message with your questions.

Contact us now