Exceeding customers' expectations is the sincere ambition of many enterprises, especially if these expectations are high and the company claims that it can relieve people of physically heavy and unhealthy work. Copal Handling Systems was founded in the belief that it can make people's lives easier and by doing so contribute to the corporate social responsibility of companies that make a living from unloading heavy bags from containers. At the same time Copal obviously sees a hole in the market.

Healthier work, less injuries and no loss of quality

A world’s leading company for container unloading, sorting and palletizing solutions

Copal Handling Systems – a contraction of container and pallet – is a young company, located in 's-Heerenberg, in the east of the Netherlands. Jan Grasmeijer has been the director Techniek for three years now. Together with René Versteeg, chief engineering, he talks about the company's activities now and in the future.

Ergonomic lifting tool

The video is loading...

Copal Handling Systems designed and constructed a machine that semiautomatically unloads containers

Jan Grasmeijer: "Given the rise in the ageing population it becomes increasingly difficult to find people who want to do the heavy work of unloading containers and prepare their contents for further transport. There are many abuses. Therefore technology must and can be used!"

The first Copal system originated as ergonomic lifting tool: An operator-controlled hydraulic balancer that has since been optimized to a point-to-point controller without hydraulics.

He continues: "The late Wim Bosman, owner and CEO of the Wim Bosman group, a global logistics provider, saw the prototype of Copal's C1 container unloader & palletizer in 2011, and immediately realized the system’s potential and the opportunities to refine it. It was also a thorn in his side that people have to lift and lug such heavy weights when unloading containers. He became a major shareholder, which the Bosman family is to the present day."

Today Copal is the world’s leading company for container unloading, sorting and palletizing solutions. And the market is unprecedentedly large with about 100 million containers travelling around the world.

Project impressions

Quote from Jan Grasmeijer, director Techniek

With our systems we want to contribute to the sustainability and social responsibility of our clients throughout the world: Healthier work, less injuries and no loss of quality. That goes hand in hand...

... in hand with the ever stricter regulations regarding weight lifting. " Copal published a white paper about the subject.

The company took off by developing and constructing systems for the unloading of bagged goods: Cocoa, nuts and coffee in jute bags, to be picked up by means of grippers with needles. In the future Copal will be concentrating more on boxes and ways to unload, sort and stack these smoothly.

C2 Mobile container unloader

A new application of the C2 unloaders is movable. The unloaders can be operational within 15 minutes and can be deployed in multiple locations, both indoors and outdoors, to unload bags. Only one operator performs small corrections via a touchscreen and joystick from his cabin using cameras.

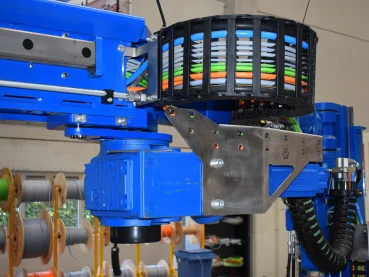

By means of the SpiderGripper gunny sacks containing nuts, coffee or cocoa to 100 kg can be lifted and rotated 360 degrees. A motion controller takes care of the automatic positioning of the gripper. Software scans and determines the order of discharging the bags. The gripper contains a very flexible mechanism with multiple rotation and tilting points that seizes bags by means of needles and shifting them in one flowing movement.

Thanks to these smooth machine movements the work can be done much faster, increasing productivity, without physical efforts for the operator. Also bags that, for example, lie diagonally across each other, can be picked up and positioned straight on a conveyor belt. A robot palletizer stacks the bags to almost 2 m on pallets, in multiple stacking patterns.

Optional sensors can check the degree of the bags' humidity. Additionally samples can be taken from the bags randomly.

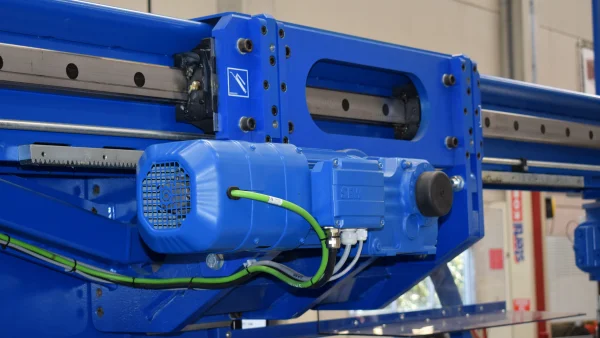

Drive and control technology

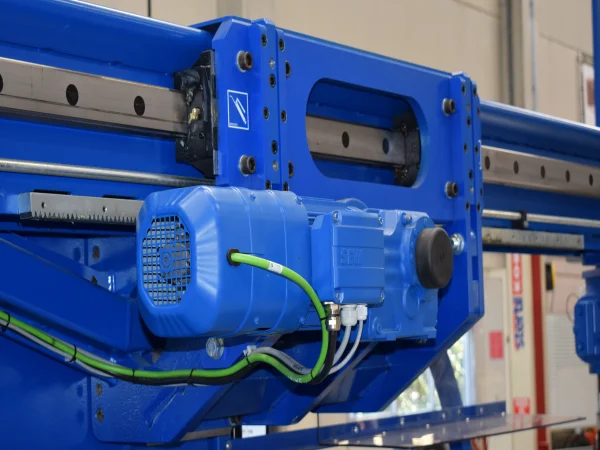

The systems that Copal manufactures are complex. For the drive technological and control technical knowledge the company called in SEW-EURODRIVE (see below). SEW plays an important role in the development of the kinematics. Together with Copal it takes care of an integral control platform and helps to collect data.

Grasmeijer: "The local presence of SEW on all continents has been an important factor to Copal when opting for a vendor. A machine must be back into operation within 4 hours. Being a dynamic company we do not want to build up a whole service organization ourselves. We hold the opinion that following the whole life cycle is a joint responsibility."

René Versteeg: "SEW-EURODRIVE is one of our core suppliers who supports us in ensuring a high degree of automation. Our greatest challenge is to prevent failures and if they occur, to solve these as quickly as possible. Therefore predictive maintenance is essential, for example, by remote diagnosis."

Quote from Jan Grasmeijer about the support from SEW-EURODRIVE

"Copal is confident that together with SEW we can provide an impeccable operation of our systems. As a matter of fact our customers often only have a forklift and scales and...

Components

SEW's role in a limited space

Copal asked SEW-EURODRIVE for its support in calculating the kinematic model. This model describes all movements that have to be performed. The gist of it is that basically four movements have to be made based on a so-called LRRL (linear – rotating – rotating – linear) pattern.

Three of the four movements (X (horizontal) axis, parallel-arm and lifting mast) occur via electrically powered axes. The fourth axis (lifting mast - linear) is carried out hydraulically, but is integrated into the motion model and is steered by the SEW motion controller.

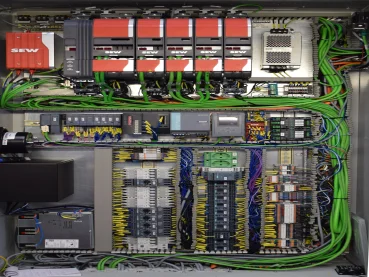

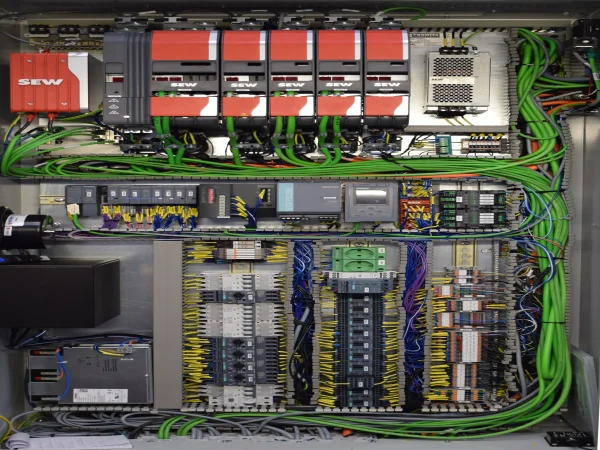

It concerns the MOVI-C® type UHX84-A-R/OMH84, the heart of the control system of the kinematic model that calculates the paths to follow. The kinematic axes are controlled via Ethercat and provided with new (position) information every millisecond. In total there are six axis modules for ten (a)synchronous servo motors. The hydraulic lifting mast cylinders are controlled through SEW Ethercat remote I/O.

The challenge in the machine's design and construction is situated in the limited space to move, not allowing a standard industrial robot as an option. For that reason the modular automation platform MOVI-C® from SEW was given preference.

The MOVI-C® platform consists of engineering software, control technology, centralized and decentralized inverters and drive technology. The MOVI-C® is very compact because of the double-axis modules: One axis module is able to control two motors, so that only one servo inverter is needed.

Because of the compact space one must always take account of the place where the bags are deposited. It is a game between speed and reliability: To choose the fastest path without the elbow of the machine touching the container and damaging itself. The machine’s space to move is determined by the height of the container. The width is standard, but the height is not, because of 'normal' and 'high cube’ containers.

The used gearboxes (amongst others type KAF) are – as far as possible – provided with reduced backlash. This ensures a direct and smooth movement. Moreover asynchronous SEW motors are applied, while other manufacturers have to resort to servo motors. The SEW AC motors have a higher inertia than synchronous motors and can therefore better handle heavier loads (the inertia proportions are more balanced).

Copal Handling Systems and SEW-EURODRIVE want to strengthen their partnership, so that we can continue to count on each other. This includes: Exchange of technical knowledge, think along with each other about solutions and transparency. Continuity is crucial in our branch of sport.

Click on Copal Handling Systems for more information.

Contact

Feel free to contact us!

Do you need advice on a specific application? Just send us a message with your questions.

Contact us now