The assembly hall of Apollo Engineering sounds hollow for a while. The cover distribution and buffer station project has been supplied to the customer in Nigeria, which creates room for the next job for the people of the technical machine construction consulting firm. The name of Apollo suggests that the company has guts and pushes its boundaries. Not into the direction of the moon, but in the field of electro-techniques and mechanical engineering.

Apollo Engineering came into existence in 1986 when two enterprising mechanical engineers, Frits de With and Martinus van der Meulen, started a construction and consulting firm focused on mechanical engineering. The small company started in a shop-premises between church and pub and expanded quickly. The current building in Aldeboarn, Friesland, was moved into in 1996. The assembly hall expanded with the size of the machines that were built.

Ing. Bauke van den Akker, managing director: ”We are a technical consulting firm for mechanical engineering and we ship our machines around the world from the heart of Friesland. With our 28 employees we master several disciplines”. For example Apollo Engineering takes care of the mechanical engineering of machines for companies like Kuipers Food Processing Machinery (chips and peanut lines). It seconds its engineers to customers like Huhtamaki, manufacturer of packing material, to upgrade the machinery. It develops and constructs machines for the packing industry, for example to position boxes, pack, close and open them: from design, construction, cabling and installation, completely tailor-made. Gerard Lourens, electrical engineer: “We construct reliably and well thought-out and don’t accept risks with regard to operational safety.”

The strength of Apollo Engineering

Ing. Bauke van den Akker: “Our strength? We rely on our electrical and mechanical knowledge, we are creative, approachable, every inch mechanical engineers, innovative, realistic, we speak the language of our customers and are not tied to suppliers.” As exemplary projects he states the packing and unpacking for round and oval pots, a machine for emptying trays with freeze-dry coffee, a supply system for packing hand-rolling tobacco, bottles containing radioactive fluid for medical purposes…

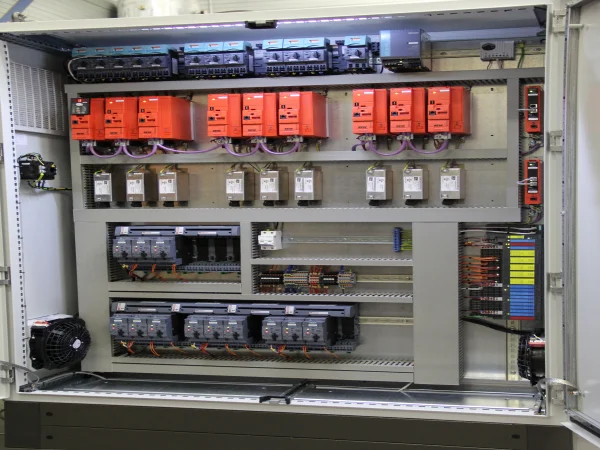

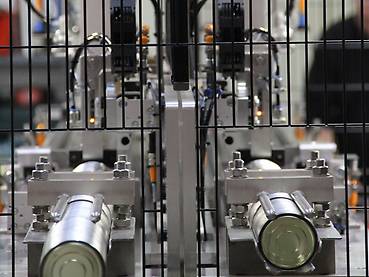

Gerard Lourens tells enthusiastically about a recent project that from beginning to end – from design table to putting into operation – was done for a large dairy products manufacturer in Nigeria: The construction of a distribution and buffer station for can covers for the packing of condensed milk. Up to 3,200 covers are being processed per minute in this station. Apollo Engineering improved the process in such a way that the processing of covers still continues even if there is a standstill further down the line. The installation is saturated with SEW drives and inverters: Two servo axes and 20 MOVITRAC® frequency inverters that control SEW-squirrel-cage induction motors.

Strong bonds

The bond with SEW-Eurodrive is tight and dates back to 1986. Gerard Lourens: ”If you call, you will be assisted. The sales engineers are experts and think along with you. The SEW tools, for example to generate 3D drawings, are handy. And the international presence of SEW is important. If a machine breaks down in China or Brazil, a local SEW mechanic is send to the job.” Not in a rocket, but in a well-equipped service automobile.

Contact: Roy Burger

Project impressions

Components

Feel free to contact us!

Do you need advice on a specific application? Just send us a message with your questions.

Inquire now